Yast-JD250,is a fully automatic flat/v sharp bottom paper bag making machine which suit for bakery ,medical,dried fruit,snack food and normal envelope,feed material,and so on.

1.From the appearance, our machine has been patented in China, beautiful appearance, clean color, less machine noise, more safe.

2.From the perspective of labor, our machine is fully automatic, touch man-machine interface, PLC control, easy to operate, simple, one person can be skilled in operation, can effectively control labor costs.

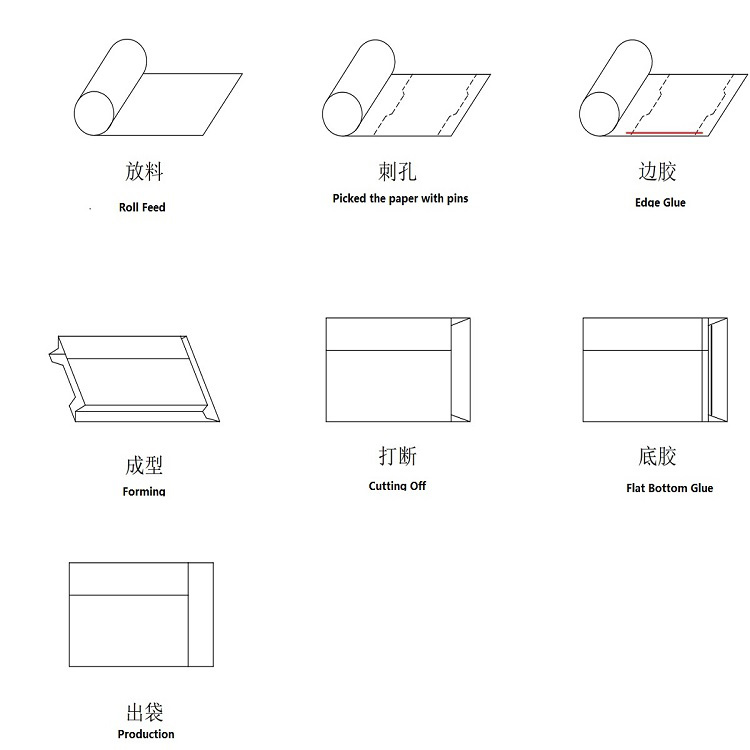

Product instruction

3.In terms of functions, the machine is mainly divided into five steps :

1). Unloading area, one health type start, raw material loading and unloading adopts hydraulic lifting structure, unwinding adopts automatic constant tension control, so that the paper will not pull and break when running at high speed, no waste.

2). Adopt German original REXROTH servo motor with German original SICK photoelectric eye correction to accurately track the size of the printed bag.

3). Raw material correction adopts Italy SELTRA to reduce the time to adjust the position of the roll.

4). Using the original Rexroth PC, through the high-speed bus Ether Cat, to ensure the stability of high-speed operation.

5). Collection part, automatic counting collection function, automatic stacking, convenient and effortless.

Product Parameter(specification)

|

Model |

YAST-JD250 |

|

Cutting length |

110-460mm |

|

Bag length |

100-450mm |

|

paper bag width |

70-250mm |

|

Insert size |

20-120mm |

|

Bag mouth height |

15/20mm |

|

paper thickness |

35-80g/m |

|

Machine speed |

30-300pcs/min |

|

paper roll width |

160-780mm |

|

Roll paper diameter |

∅1000mm |

|

Inner diameter of paper |

∅76mm |

|

Machine power |

380V 3Phase 4 lines 24kw |

|

Machine weight |

4500kg |

|

Machine size |

7100*3000*2200mm |

The flow chart

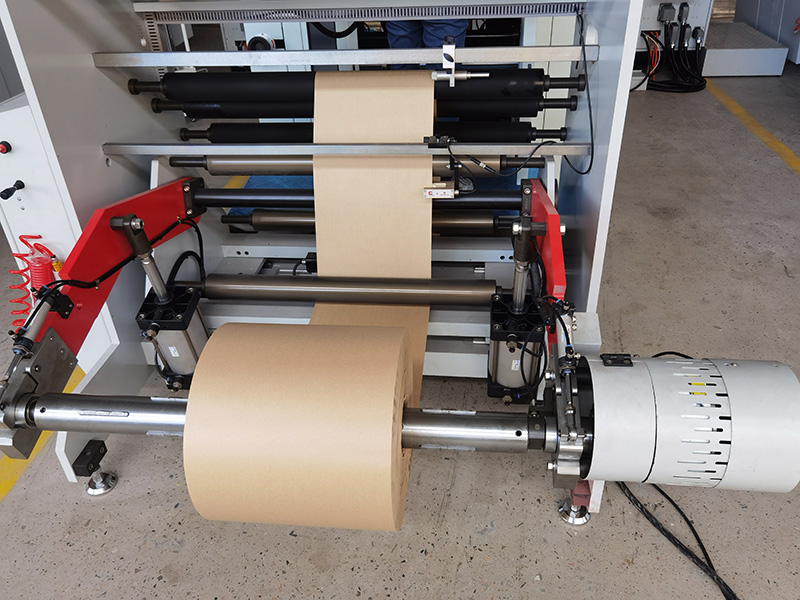

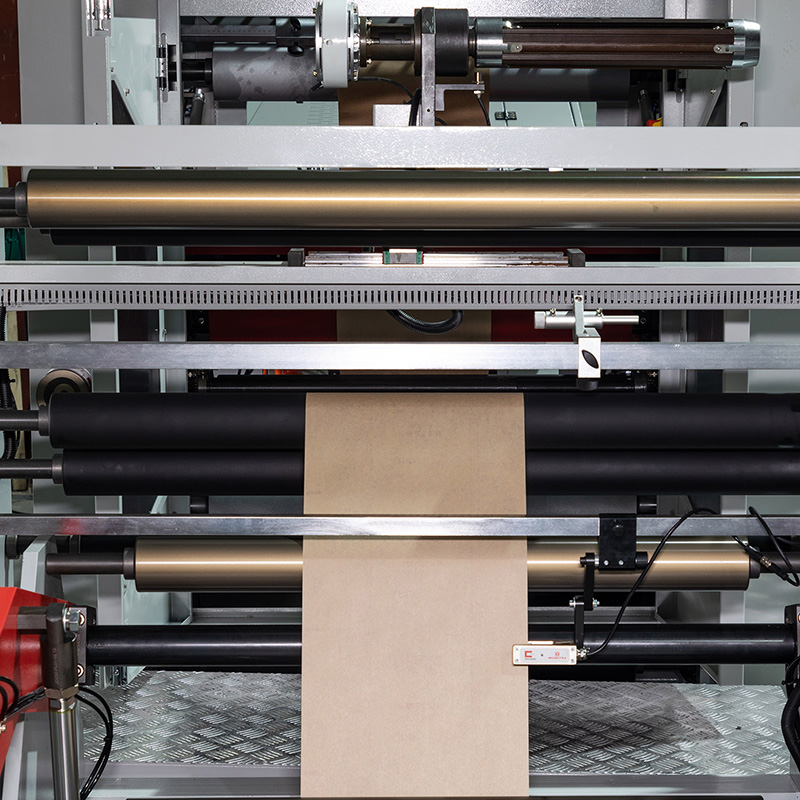

Machine details

sing the French touch screen man-machine interface control system,operating at a glance, one key to star very convenient ,it control in many languages.The bag length can adjustable.

The feeding part of the hydraulic up and down, Rolling inflatable shaft: easy to use, easy paper roll placement, saving manpower.

Taiwan magnetic brake, Taiwan power can use for a long time ,even tension control.

The edge correction adopts the ultrasonic edge-to-edge operation, which is not affected by the light source dust, the work is stable, the operation response speed is fast, and the alignment time is saved and the waste of raw materials is saved.

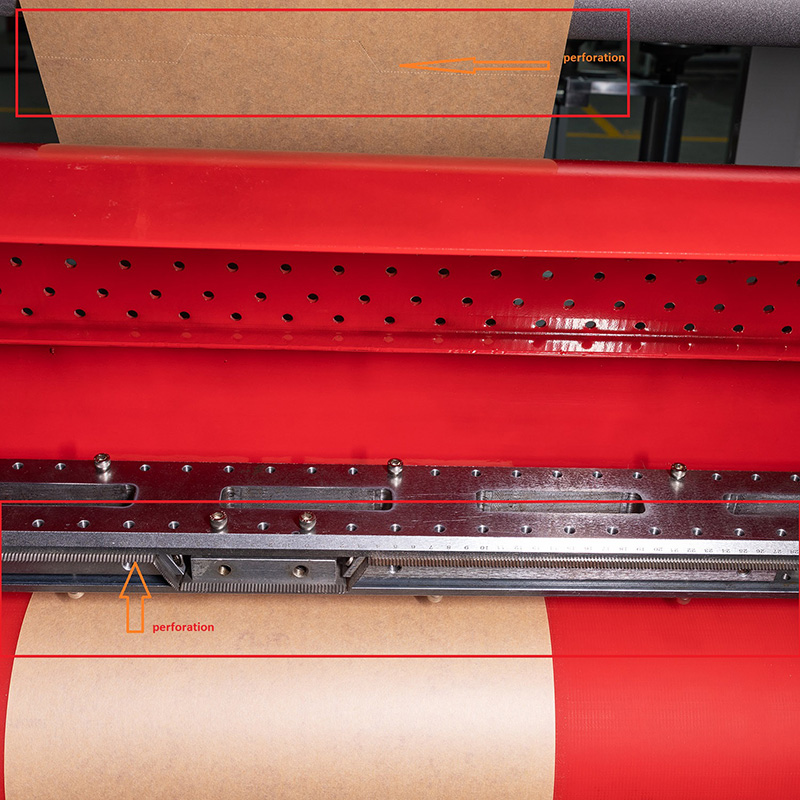

Perforation function, very good to help the length cutting, smooth and beautiful.

The belt tore the bag length.

The automatic counting function can be set, and the counting is accurate.Reach the set number will naturally be higher than the other bag prompts you.

Shipping package

Deliver and serving

*After-sale Service In the case of epidemic

1. Manuals / Videos of machine installation, adjusting,setting, maintenance are available for you.

2. If any problems happen and you can not find out the solutions, Telecom or Online face to face communication available 24 hours.

3. ICT engineers & technicians are available to send to your countries for services if you agree to pay the expenditure.

4. The machine will have a 1-year warranty for the machine,2 years warranty for the electric part. During the warranty year if any of the parts broken not by man-made.(Wear parts excepted. We 'll send you a wearing parts list). We will free charge to replace the new one for you. The warranty will begin after the machine send out we received the B/L.

Demo and Testing?

You are welcome to visit our factory anytime for the machines’ demo.

We will provide testing and running videos when the machine leaves the factory

What about warranty of machine?

We offer a 12-month warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems. All failures caused by improper use of the buyer (including unauthorized modification of PC and touch screen built-in software) are not within the scope of the warranty (except for the vulnerable parts of wearing parts).

GET A QUOTE