High speed overlapping type synchronous belt Shaft-less roll -fed flexo printing machine

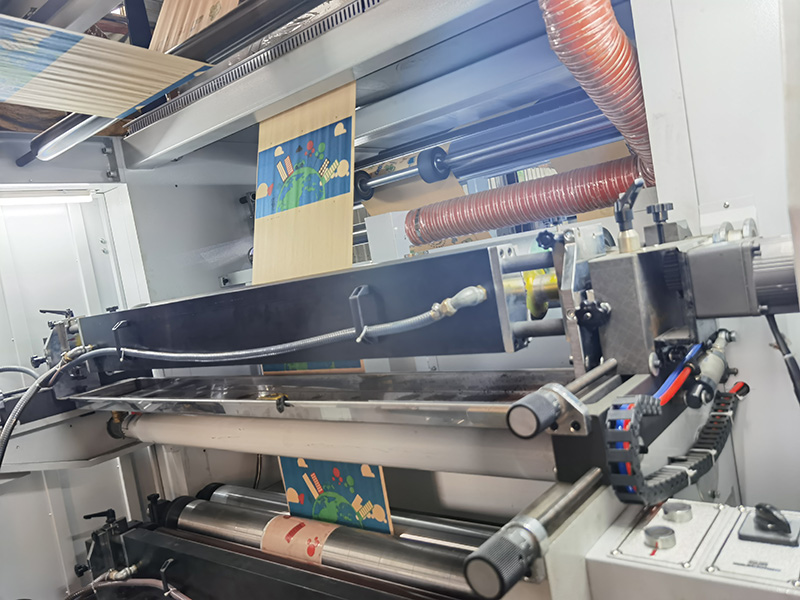

YAST-FP1200 This is a 4-color roll-to-roll flexo printer with a wide feeding width that can be customized according to the customer's size.In the unwinding unit, the traditional discharging way is changed and the moving swing arm is added. According to the wide width of the web paper fixed position, magnetic powder brakes are installed on both sides respectively, and hydraulic lifting can carry more than 1 ton of web paper. It is suitable for printing paper products such as posters, books, paper bags, paper cups, etc. It can also be used for film, wrapping paper, cellophane,copy paper,pp,LDPE and so on.

Characteristics:

1. The machine is equipped with blower and heater; and the heater employed central temperature control system.

2. The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.Adopt with external heating pipe, temperature display, electric current control,centrifugal blower bring the wind,one color one dryer.

3. Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

4. Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance, beating small, achieves finally perfect printing effect.

5.Accurate printing effect achieved by special gear transmission device.

6.The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

7.High precision planetary gear oven 360°circulation longitudinal register.

8.Inking with ceramic anilox chambered doctor blade,ink pump circulation.

9.±20mm transverse register.

10.Adjust inking press and printing pressure press by manual.

Technical Parameters

|

Model |

YAST-FP 1200mm with 4 colors |

|

Color |

4 colors |

|

Max. Printing material width |

1160mm |

|

Max. Printing width |

1160mm |

|

Max. Unwinding diameter |

1300mm |

|

Max. Rewinding diameter |

1300mm |

|

Printing length range |

228-1000mm |

|

Printing speed |

5-120m∕min |

|

Register precision |

≤±0.15mm |

|

Thickness of plate(the thickness of double sides glue:0.38mm) |

2.28mm+0.38mm |

|

Printing cylinders |

1 set |

|

Ceramic anilox |

4 pcs |

|

The machine size |

L8200mm*w2300*2800 |

Machine details

1.In the unwinding unit, the traditional discharging way is changed and the moving swing arm is added. According to the wide width of the web paper fixed position, magnetic powder brakes are installed on both sides respectively, and hydraulic lifting can carry more than 1 ton of web paper.

2.Compare with air expansion shaft more convenient and can withstand gravity.

2. Ink through ink pump automatic ink absorption, ink circulation in the closed ink cartridge, with the closed scraper, ink will not splash out, even ink jet.

3 . Pneumatic lifting and lowing printing plate cylinders auto lifting plate cylinder when the machine is stopped. After that can run ink automatically. When the machine is opening,it will make alarm to start the auto lowering plate printing cylinder.

4. Transmission between printing roller and anilox roller: Helical gears. It's a helical gear and a synchronous belt, with high accuracy and low noise,to ensure longer service life of the machine.

5. PLC touch screen control the whole machine.6 language can be switched.

6. Big roller friction rewind system for paper,Pneumatic tension control,

2.2kw motor,vector frequency conversion control,3 inch air shaft, Hydraulic lowering the material.

Shipping packing

Iron plate with film wrapped.

After-sale Service

1. Manuals / Videos of machine installation, adjusting,setting, maintenance are available for you.

2. If any problems happen and you can not find out the solutions, Telecom or Online face to face communication available 24 hours.

3. ICT engineers & technicians are available to send to your countries for services if you agree to pay the expenditure.

4. The machine will have a 1-year warranty for the machine. During the warranty year if any of the parts broken not by man-made.(Wear parts excepted.We 'll send you a wearing parts list). We will free charge to replace the new one for you. The warranty will begin after the machine send out we received the B/L.

GET A QUOTE