Description

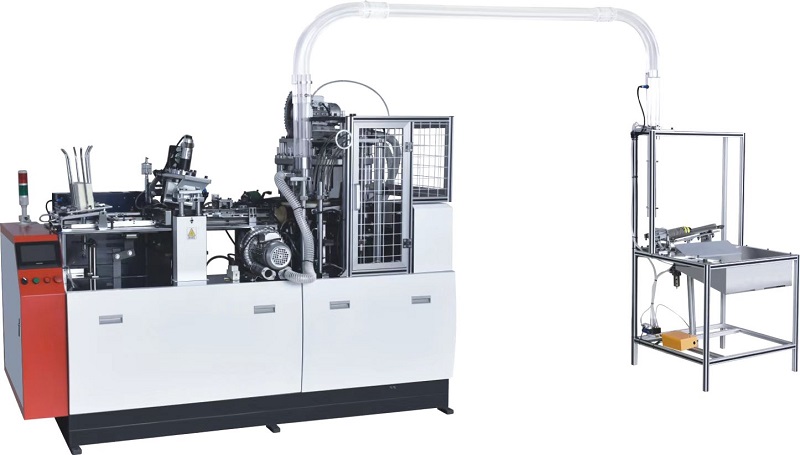

Our newly designed paper cup forming machine is a highly intelligent machine,which can produce different sizes of paper cups with a series of continuous process, including automatic paper feeding through more than 2 times, paper anti-withdrawal device (to ensure accurate positioning), ultrasonic welding, transferring paper fan by magic hand, silicone oil lubricating, bottom punching, bottom folding, bottom pre-heating, bottom knurling, cup discharging,the cup waste is automatically identified and throw out .

Characteristics

The photoelectric eye sensor from South Korea is equipped with 9 sensors from paper feeding, side sealing, cup setting, bottom punching, bottom heating, edge rolling, cup unloading, cup counting, through multiple sensors detection, can realize counting, cup dropping, bottomless, no paper and other automatic detection, alarm automatic stop and other functions.One piece feeding paper corresponding one cup bottom,never empty correspondence,PLC touch screen control, simple operation, at a glance.

Parameter

|

Model |

YAST-S800 PLC with ultrasonic and collection table |

|

Paper Cup Size |

40ML-16OZ (Mould changeable) |

|

Raw Material |

150-350g/㎡(one side or two-side PE film coated /laminated paper)±20g/㎡,200-350g paper need ultrasonic device |

|

Productivity |

75-100pcs/min |

|

Power Source |

220v/380v 50HZ/60HZ 3Phase |

|

Cup size bottom |

35-70mm |

|

Top mouth |

45-90mm |

|

High |

30-135mm |

|

Bottom Knurling Depth |

4-10mm |

|

Top Curling Rim Dameter |

Popular about ∅2.5-∅3mm |

|

Total Weight |

1800kg |

|

Machine Size |

L2000*1230*1700mm |

|

Working Air Source |

0.4-0.6MPA,0.4m3/min |

|

Machine power |

6.5kw |

|

Bottom knurling |

HOT AIR SYSTEM |

|

We used 380v,if you power is different , please declare in advance. |

|

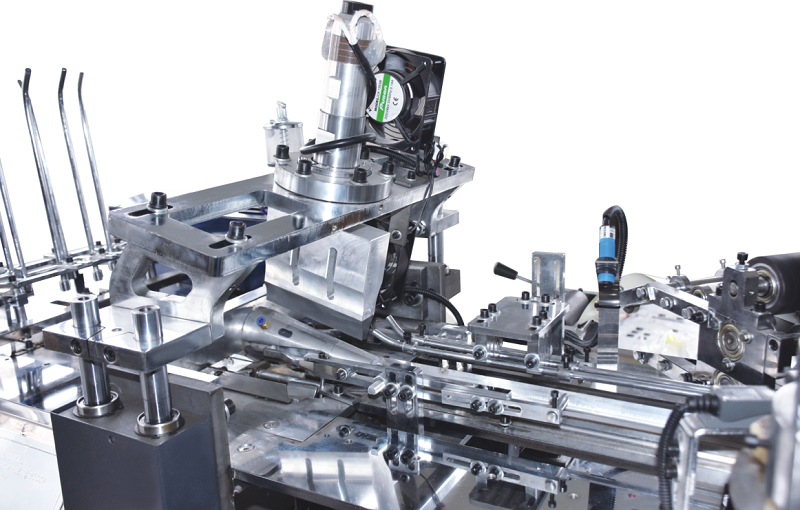

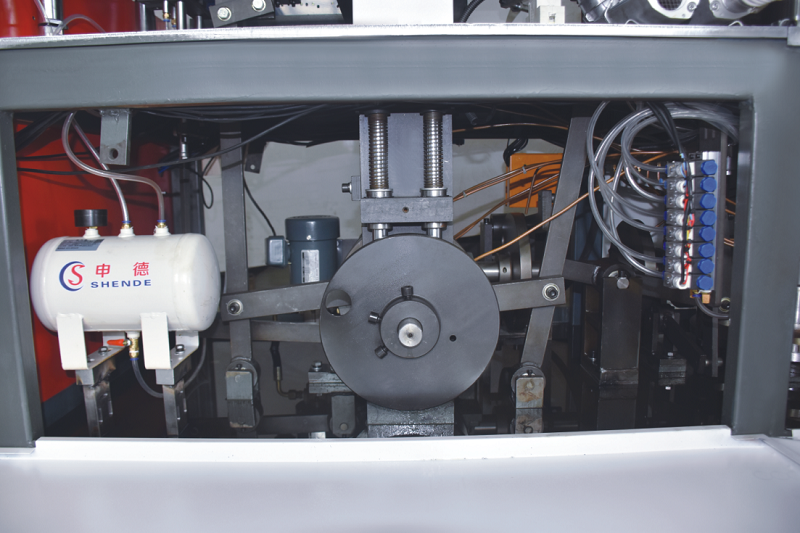

Machine Detail

Ultrasonic heating device, single coated or double coated paper bonding more smooth and firm, beautiful.Through ultrasonic heat sealing, the paper cup does not leak, and the edge is smooth and beautiful,and the firmness is higher than that of copper strip heating.

Built-in gas tank,make the machine more dynamic and stable , Cam contro paper suction and cup transfer intergration,make the machine more accuate.

Remarks:

After sale service:

FAQ:

1.Where is your factory located?

We are the factory that located at Wenzhou City, Zhejiang Province.

2.How long it will be take from Guangzhou to Your factory?

It will be about 2 hours flight from Guangzhou Airport to our Wenzhou Airport

3. Are you manufacturer or trade company?

We are manufacturer,and we also do export business.

4.How to get in touch with us?

Login to the official website:www.yastermachine.com

Call us directly :+86 18058385050

Direct to the company: No.9 Western road ,Yangdi, Xincheng town,Ruian Town, Wenzhou city, zhejiang province ,China .

5.Which payment form you can accept?

T/T, L/C,Western Union, PayPal etc.Please check with us before payment.

GET A QUOTE