YAST-FD190 automatic square bottom paper bag machine use paper roll in blank or printed as raw material, consists of automatic centre forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time, The machine is more convenient, more efficient, more stable, can produce a variety of different paper bags, leisure food bags, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

The whole machine is controlled by computer central control system, touch screen display, servo motor control paper bag length, can produce multiple specifications of paper bag.

|

Model |

YAST-FD190 |

|

Cutting length |

190-370mm |

|

paper bag width |

80-190mm |

|

paper bottom width |

50-105mm |

|

paper thickness |

50-130g/㎡ |

|

Machine speed |

30-260pcs/min |

|

Production speed |

30-200pcs/min |

|

paper roll width |

280-640mm |

|

Roll paper diameter |

∅1300mm |

|

Inner diameter of paper |

∅76mm |

|

Machine power |

380V 3Phase 4 lines 11.5kw |

|

Machine weight |

6000kg |

|

Machine size |

8500*3500*2200mm |

1.Use France Schneider Touch Screen Human-Computer interface, operate and control easily.

2.Adopt Germany Original REXROTH PC Control, Integrated with optical fiber, ensure high speed running steadily.

3.Germany Original REXROTH SERVO MOTOR and Germany Original SICK PHOTOELECTRIC Correction, tracking printing bag accurately.

4.Raw material load adopt hydraulic pressure up and down structure, unwinding adopt auto tension control.

5.Raw material unwinding EPC adopt Italy SELECTRA, reduce adjustment time.

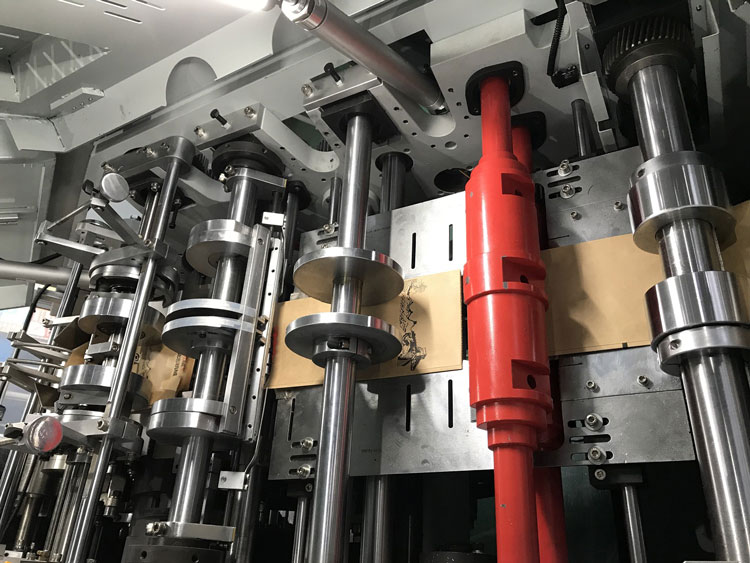

Rolling inflatable shaft: easy to use, adopt automatic Hydraulic cylinder, make it automatic to load the roll up and down, just by pressing the button to start the cylinder. Help you out of any carry job.

The paper tube forming adopts an integrated tube forming adjustment structure, which can be adjusted in one or two directions. The adjustment is simple, convenient, fast, and stable.

The cutting traction adopts the German REXROTH servo motor to control and adjust the paper bag size.The cutting adopts a high-speed uniform rotating cutter to cut through a serrated knife or a flat knife. The appearance of the paper bag cut is smooth and beautiful.

The bottom of the bag is folded and formed, and the bag is pressed flat through the hub wheel, so that the bag is more convenient for storage and sorting,automatic bottom gluing.

The automatic counting function can be set, and the counting is accurate.Reach the set number will naturally be higher than the other bag prompts you.

1.Inquiry and consulting support.

2.The latest industry trends.

3.More fit bag making solution.

4.Sample testing support.

5.View our factory.

6.Suggest layout support.

1.Global online service.

2.Engineer regular return visit service.

3.Independent service department with 40 senior engineer.

4.One year warranty.

5.Machine test video before delivery.

6.English manual , electric diagram.

7.Training how to install and running the machine.

GET A QUOTE