1. Machine use roller paper, from primary color paper or printed web paper to square bottom paper bag one times production.The machine can be used in various paper bags with high speed and efficiency. It is an ideal equipment for paper bag production.

2.This machine is composed of roll unwinding (hydraulic feeding, automatic web guide, constant tension), center-forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. This machine really realized that full automation production can effectively save the labor cost.

|

Model |

YAST-FD220 |

YAST-FD280 |

|

Cutting length |

190-370mm |

190-370 |

|

Paper bag length |

150-320mm |

150-320mm |

|

paper bag width |

80-220mm |

80-280mm |

|

paper bottom width |

50-120mm |

90-180mm |

|

paper thickness |

50-130g/m |

80-150g/m |

|

Machine speed |

30-220pcs/min |

30-200pcs/min |

|

Production speed |

30-200pcs/min |

30-150pcs/min |

|

paper roll width |

280-710mm |

660-1290mm |

|

Roll paper diameter |

∅1200mm |

∅1300mm |

|

Inner diameter of paper |

∅76mm |

∅76mm |

|

Machine power |

380V 2Phase 4 lines 10kw |

380V 3Phase 4 lines 15kw |

|

Machine weight |

5500kg |

9000kg |

|

Machine size |

9000*3200*1800mm |

1000*3800*2200mm |

1.Use France Schneider Touch Screen Human-Computer interface, operate and control easily, one key to star, whole machine only use 1 or two labors.

2.Adopt Germany Original REXROTH PC Control, Integrated with optical fiber, ensure high speed running steadily. There is an automatic alarm system, automatic stop in case of failure.

3.Germany Original REXROTH SERVO MOTOR and Germany Original SICK PHOTOELECTRIC Correction, tracking printing bag accurately.

4.Raw material load adopt hydraulic pressure up and down structure, unwinding adopt auto tension control.

5.Raw material unwinding EPC adopt Italy SELECTRA, reduce adjustment time.

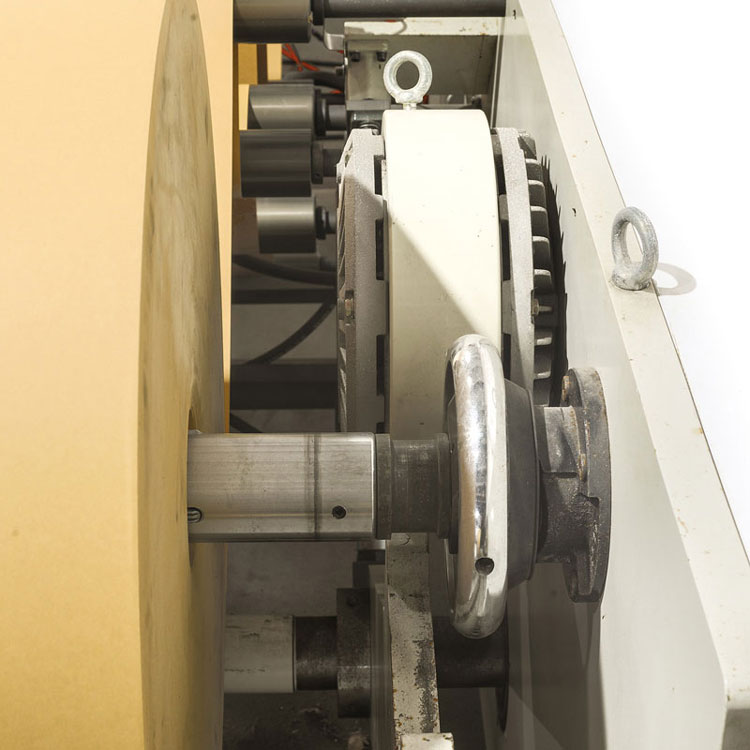

Rolling inflatable shaft: easy to use, adopt automatic Hydraulic cylinder, make it automatic to load the roll up and down, just by pressing the button to start the cylinder. Help you out of any carry job.

Magnetic powder controller, tension control,constant tension control system, quick response, simple structure, high control precision, long life, stable rotation.

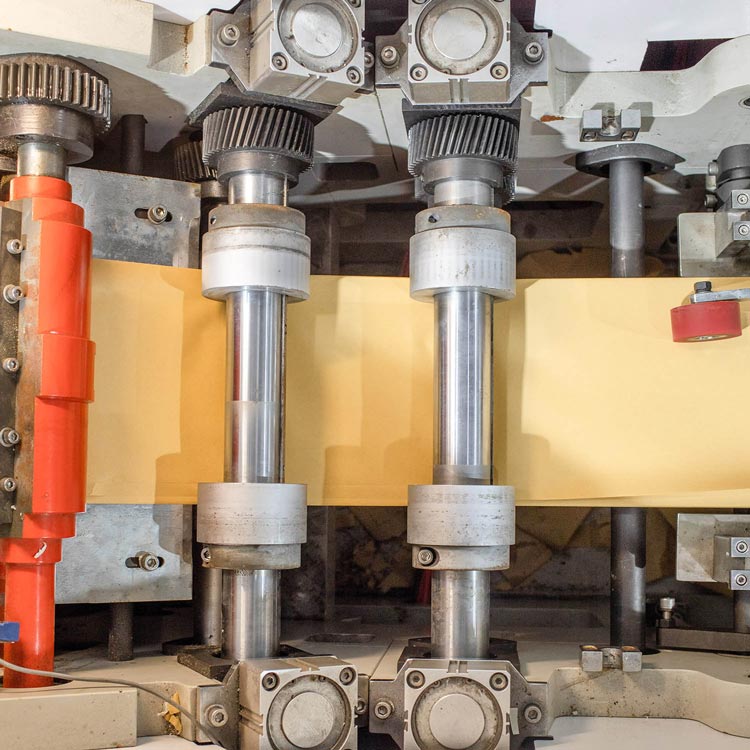

The paper tube adopts adjustable structure, can be adjust in single or both direction , bag width size is the size of the replacement template, different bag width size, different template.

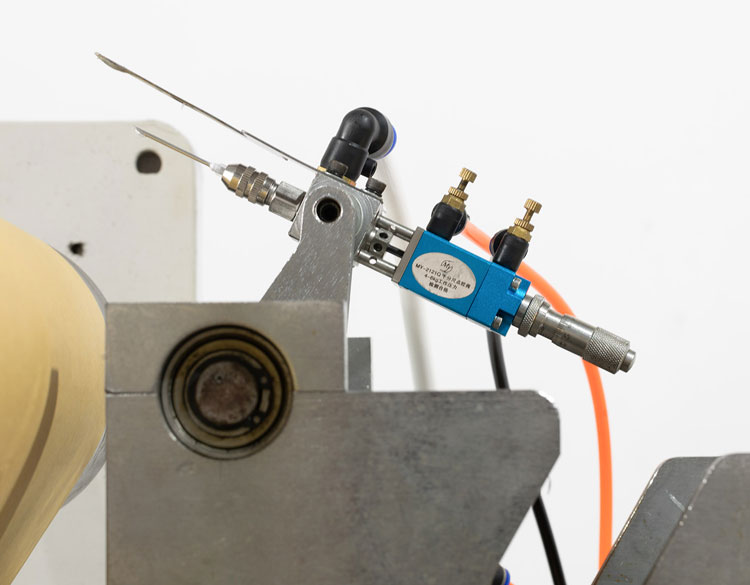

Side glue adopts automatic spray glue, spray glue quantity is uniform, the amount of glue can be adjusted.

Adopt energy-saving pressure rubber bucket, easy to use, save glue, no need to clean

Cutting can be done with a serrated knife or a flat knife,Cutting can be cut by serrated knife or flat knife, serrated knife cut out the bag mouth like teeth, flat knife incision is flat,You can choose one way.

Fully enclosed dust-free electrical control box, equipped with automatic air conditioning constant temperature to protect electrical appliances long service life.

Using the French SCHNEIDER touch screen man-machine interface control system, the operation interface is clear at a glance, the reflection is sensitive, and it is not easy to malfunction and break.

Q: What information should I let you know if I want to get a quotation?

A: First, Paper raw material: Reel paper or Sheet Paper.

Second, sizes of the paper bag, thickness of paper.

Send sample bag picture if available.

Q: What is the payment term?

A: After signing of the contract, the total amount of 30% advance payment, factory acceptance payment before delivery after the machine testing is ok.

Q: How long is the delivery time?

A: About 60 working days after receiving the deposit. The factory will decide whether to change the delivery date when the order is confirmed.

Q: How long is the guarantee time?

A: We offer a 12-month warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems. All failures caused by improper use of the buyer (including unauthorized modification of PC and touch screen built-in software) are not within the scope of the warranty (except for the vulnerable parts of wearing parts).

Q: what can you buy from us?

A: Paper Bag Making Machine, Non-Woven Bag Making Machine, Printing Machine, Disposable epidemic prevention equipment machine.

Q: What about spare parts?

A: We have a list of accessories, including wearing parts. We will send you an extra pair of wearing parts for spare. We will teach you how to replace the wearing parts by video.

Q: How to install?

A: For the purchase of new machines for customers, our company can arrange engineer to install machinery and for the training of machine operators; for the second time or more need to move Machine and training services, our company provides compensation for the movement and training services.

GET A QUOTE