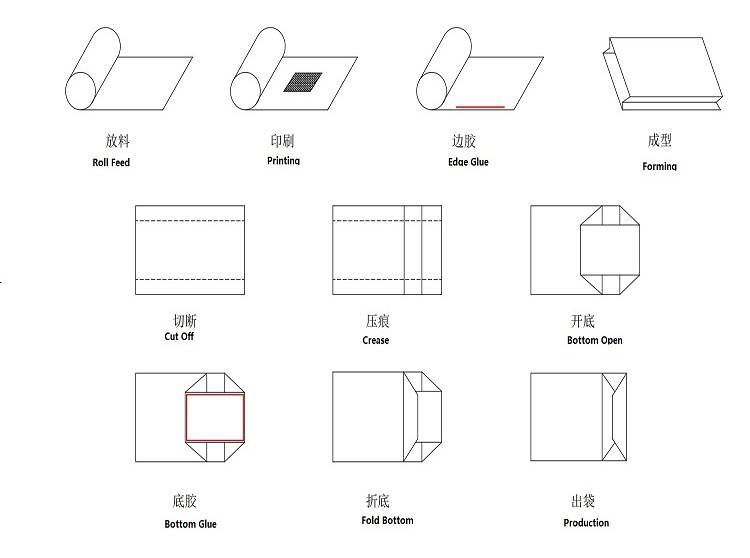

Rolling feed square bottom paper bag making machine, it uses paper roll in blank or printed as raw material. Consists of automatic centre forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time, the machine is more convenient, more efficient, more stable ,can produce a variety of different paper bags ,leisure food bag, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

|

Model |

YAST-FD330C 2/4colors |

YAST-FD190C 2/4colors |

YAST-FD450C 2/4colors |

|

Cutting length |

270-530mm |

190-370mm |

270-530mm |

|

paper bag width |

120-330mm |

80-190mm |

210-450mm |

|

paper bottom width |

60-180mm |

50-105mm |

60-180mm |

|

paper thickness |

60-150g/㎡ |

50-130g/㎡ |

60-150g/㎡ |

|

Machine speed |

30-220pcs/min |

30-260pcs/min |

30-220pcs/min |

|

Production speed |

30-180pcs/min |

30-200pcs/min |

30-180pcs/min |

|

paper roll width |

380-1050mm |

280-640mm |

590-1290mm |

|

Printing width |

380-1050mm |

280-640mm |

590-1290mm |

|

Printing length |

270-520mm |

190-370mm |

270-520mm |

|

Printing speed |

10-100m/min |

10-120m/min |

10-100m/min |

|

Color accuracy |

≦±0.20mm |

≦±0.20mm |

≦±0.20mm |

|

Plate thickness |

2.28mm+0.38mm |

2.28mm+0.38mm |

2.28mm+0.38mm |

|

Roll paper diameter |

∅1300mm |

∅1300mm |

∅1300mm |

|

Inner diameter of paper |

∅76mm |

∅76mm |

∅76mm |

|

Machine power |

380V 3Phase 4 lines 22.9kw |

380V 3Phase 4 lines 22.9kw |

380V 3Phase 4 lines 22.9kw |

|

Machine weight |

8400kg/2colors 10400kg/4 colors |

7800kg/2colors 8400kg/4 colors |

10400kg/2colors 10700kg/4 colors |

|

Machine size 2color |

11000*3500*2800mm |

11000*3500*2800mm |

11000*3500*2800mm |

|

4colors |

11500*3500*2800mm |

11500*3500*2800mm |

11500*3500*2800mm |

1.Use France Schneider Touch Screen Human-Computer interface, operate and control easily.

2.Adopt Germany Original REXROTH PC Control, Integrated with optical fiber, ensure high speed running steadily.

3.Germany Original REXROTH SERVO MOTOR and Germany Original SICK PHOTOELECTRIC Correction, tracking printing bag accurately.

4.Raw material load adopt hydraulic pressure up and down structure, unwinding adopt auto tension control.

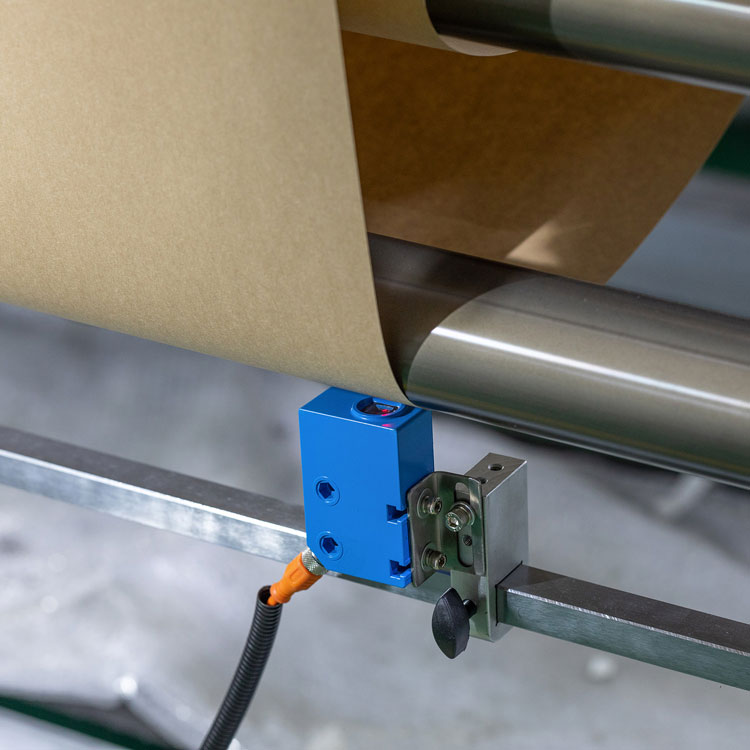

5.Raw material unwinding EPC adopt Italy SELECTRA, reduce adjustment time.

Rolling inflatable shaft: easy to use, adopt automatic Hydraulic cylinder, make it automatic to load the roll up and down, just by pressing the button to start the cylinder. Help you out of any carry job.The whole machine picture with 2 colors or 4 colors.

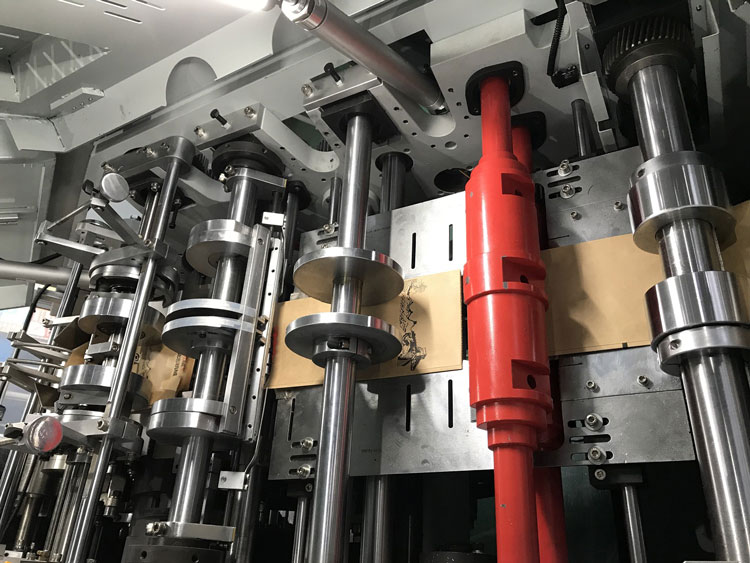

1. Printing section.1.Pneumatic lifting and lowing printing plate cylinders auto lifting plate cylinder when the machine is stopped. After that can run ink automatically. When the machine is opening,it will make alarm to start the auto lowering plate printing cylinder.

2. Ceramic anilox, above the ink grid smaller print pattern more clear, higher quality than metal anilox printing.

3. Ink through ink pump automatic ink absorption, ink circulation in the closed ink cartridge, with the closed scraper, ink will not splash out, even ink jet.

Color code tracking: Adopting German SICK color code photoelectric tracking, accurate tracking of paper bag printing patterns, automatic color code registration, no need to re-adjust the cutting position when changing paper rolls or power failure, automatic shutdown of color code errors, reducing scrap rate .

The bottom of the bag is folded and formed, and the bag is pressed flat through the hub wheel, so that the bag is more convenient for storage and sorting 。

The automatic counting function can be set, and the counting is accurate.Reach the set number will naturally be higher than the other bag prompts you.

We offer film wrapped in side and fumigation wooden outside.

About 60 working days after receiving the deposit. We offer FOB price, Ningbo port. After signing of the contract ,the total amount of 30% advance payment, factory acceptance payment before delivery after the machine testing is ok.

1.Q: offers you the how to pre-sale service? Such as: whether or not to provide the sample? Sample charges? Where the party to bear the freight?

Answer: can free to provide customers with bag samples were real machine proofing , and shooting video for customer reference.

Send in the proofing paper provided by the customer, the paper freight provided by the customer, to complete the sample bag proofing can be sent free of charge by our company.

2.Q: you provide the service of how the sale? Such as: supplying method of wearing parts? 3.Q:Delivery cycle (orders started)?

Answer: the damage in the warranty period of the fittings, our company in accordance with the warranty for its free replacement. Product delivery cycle is generally for the signing of the contract within 45 days from the date of.

4.Q: after sale service? Such as shelf life? How to provide service within the warranty period?

Answer: can provide 1 years of free warranty, long-term training services (the first free, second or subsequent training fees), the warranty period of machine parts can be damaged According to the number of free replacement parts.

5.Q: other special services? Such as the design, customization, installation, training and other services!

Answer: other services include free training for the first time, subsequent paid training, and other technical support.

GET A QUOTE