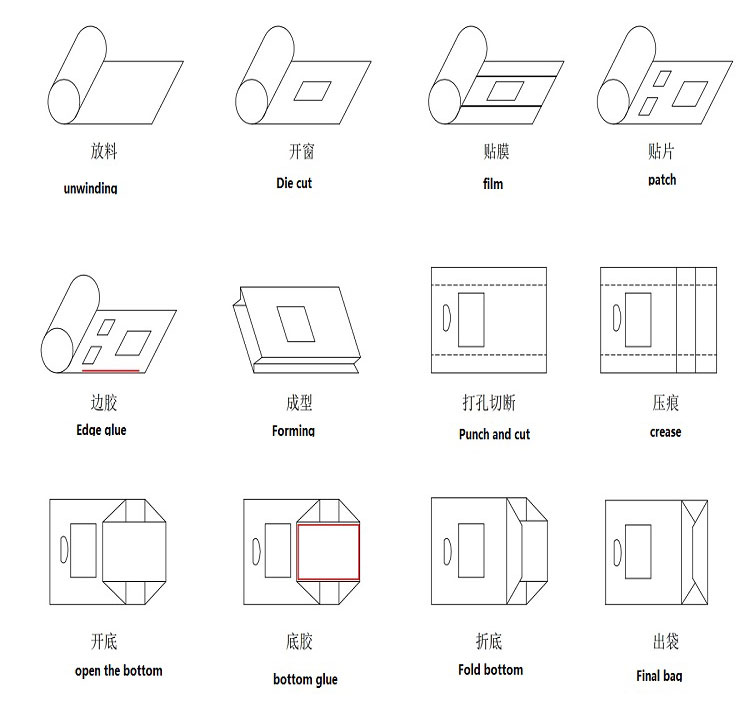

YAST-FD330D paper bag making machine with D-cut inline, is used for producing different sizes of window pasting paper bags, which are as the material of rolling paper and OPP thin film. It uses paper roll or thin film in blank or printing as material ,through the machine to finish bag making automatically, from the rolling paper form feed, automatic adjust、label tracking, drum paper rolling type windowing, hot melt adhesive film in the window, top roller glue, fold into cylinder, film cutting , bag forming , end-finished, automatically counting, etc. This machine is in high degree of automatically. Easy operation, adopting the import electric control system. With stable performance, is an ideal equipment to produce paper bags.

|

Model |

YAST-FD330D |

|

Cutting length |

270-530mm |

|

paper bag width |

120-330mm |

|

paper bottom width |

60-180mm |

|

paper thickness |

60-150g/m |

|

Machine speed |

30-220pcs/min |

|

Production speed |

30-200pcs/min |

|

paper roll width |

450-1050mm |

|

Patch bag width |

190-330mm |

|

Patch handle length |

75/85mm |

|

Patch bag paper thickness |

80-150g/㎡ |

|

Patch bag film thickness |

40-70μm |

|

Patch bag roll width |

130mm |

|

Patch bag roll straight |

500mm |

|

Patch bag speed |

30-130pcs/min |

|

Roll paper diameter |

∅1200mm |

|

Inner diameter of paper |

∅76mm |

|

Machine power |

380V 3Phase 4 lines 40.6kw |

|

Machine weight |

9000kg |

|

Machine size |

12000*3750*2000mm |

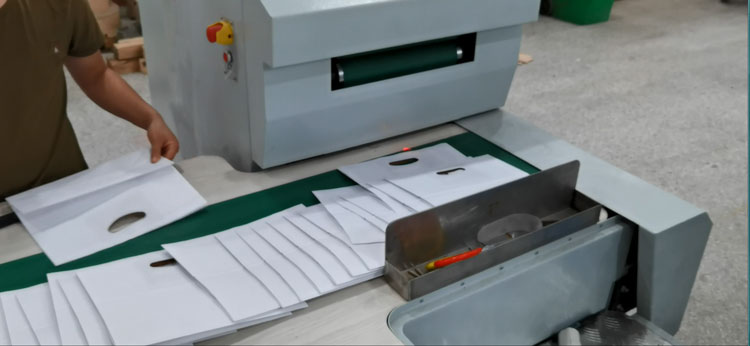

As a function extension of traditional model of paper bag machine, this kind of machine can make paper bags without handles inline from paper roll, thus it is an ideal equipment for producing paper bags fast. This kind of machine can produce paper bags of varying greatly sizes at a high speed, thus it is especially suitable for being in food and clothing industries.

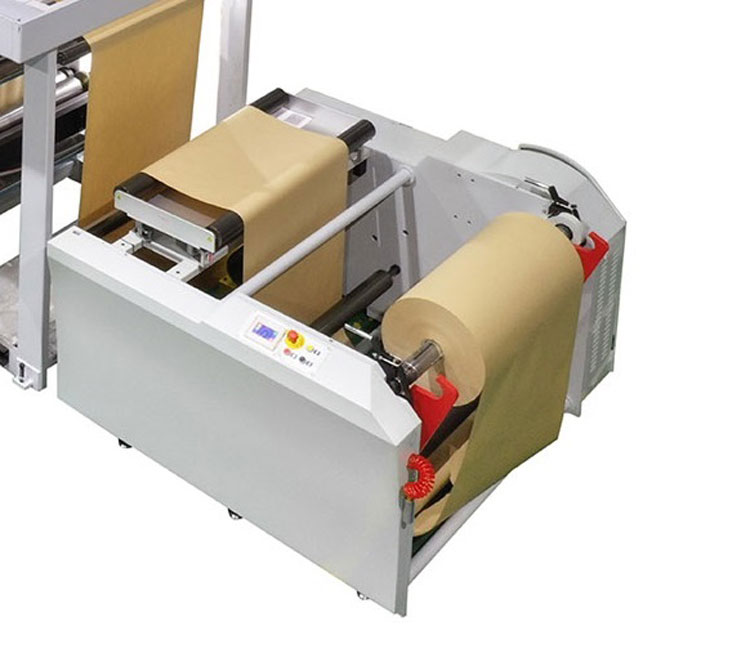

Rolling inflatable shaft: easy to use, adopt automatic Hydraulic cylinder, make it automatic to load the roll up and down, just by pressing the button to start the cylinder. Help you out of any carry job.

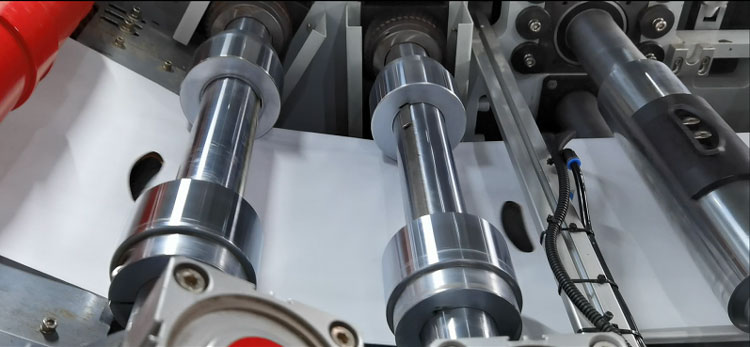

D- CUT device, handle adhesive part can be made of white Kraft paper, brown Kraft paper or film.

The handle adhesive part is automatically glued and formed.

Handle automatic punching, precise position, inductor sensing.

The automatic counting function can be set, and the counting is accurate.Reach the set number will naturally be higher than the other bag prompts you.

1.After signing of the contract ,the total amount of 30% advance payment, factory acceptance payment before delivery after the machine testing is ok.

2.About 30 working days after receiving the deposit. The factory will decide whether to change the delivery date when the order is confirmed.

3.Engineers are available to install and debug door to door and overseas. The cost for overseas will be for the buyer’s account, including visa charge, food, accommodation, around air tickets, and salary of 100usds daily one person.

*After-sale Service In the case of epidemic

1. Manuals / Videos of machine installation, adjusting, setting, maintenance are available for you.

2. If any problems happen and you can not find out the solutions, Telecom or Online face to face communication available 24 hours.

3. ICT engineers & technicians are available to send to your countries for services if you agree to pay the expenditure.

4. The machine will have a 1-year warranty for the machine, 2 years warranty for the electric part. During the warranty year if any of the parts broken not by man-made. (Wear parts excepted. We 'll send you a wearing parts list). We will free charge to replace the new one for you. The warranty will begin after the machine send out we received the B/L.

GET A QUOTE