Rolling feed square bottom paper bag making machine , it uses paper roll in blank or printed as raw material. Consists of automatic centre forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time, the machine is more convenient, more efficient, more stable ,can produce a variety of different paper bags ,leisure food bag, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

|

Model |

YAST-FD330P |

YAST-FD450P |

|

Cutting length |

270-530mm |

270-530mm |

|

paper bag width |

120-330mm |

210-450mm |

|

paper bottom width |

60-180mm |

90-180mm |

|

paper thickness |

80-150/㎡ |

60-150/㎡ |

|

Machine speed |

30-220pcs/min |

30-200pcs/min |

|

Production speed |

30-180pcs/min |

30-150pcs/min |

|

paper roll width |

380-1050mm |

590-1290mm |

|

Roll paper diameter |

∅1300mm |

∅1300mm |

|

Inner diameter of paper |

∅76mm |

∅76mm |

|

Machine power |

380V 3Phase 4 lines 16.5kw |

380V 3Phase 4 lines 16.5kw |

|

Machine weight |

9700kg |

10000kg |

|

Machine size |

13000*2700*2400mm |

13000*2700*2400mm |

1.Use France Schneider Touch Screen Human-Computer interface, operate and control easily.

2.Adopt Germany Original REXROTH PC Control, Integrated with optical fiber, ensure high speed running steadily.

3.Germany Original REXROTH SERVO MOTOR and Germany Original SICK PHOTOELECTRIC Correction, tracking printing bag accurately.

4.Raw material load adopt hydraulic pressure up and down structure, unwinding adopt auto tension control.

5.Raw material unwinding EPC adopt Italy SELECTRA, reduce adjustment time.

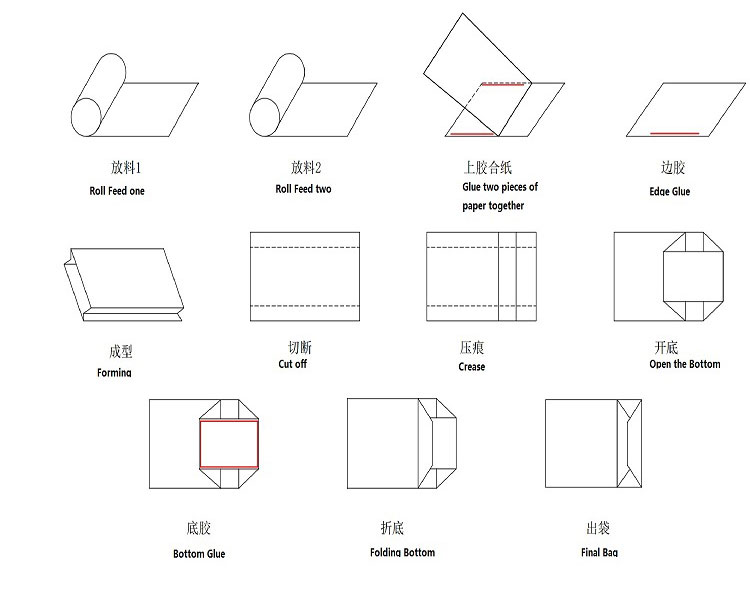

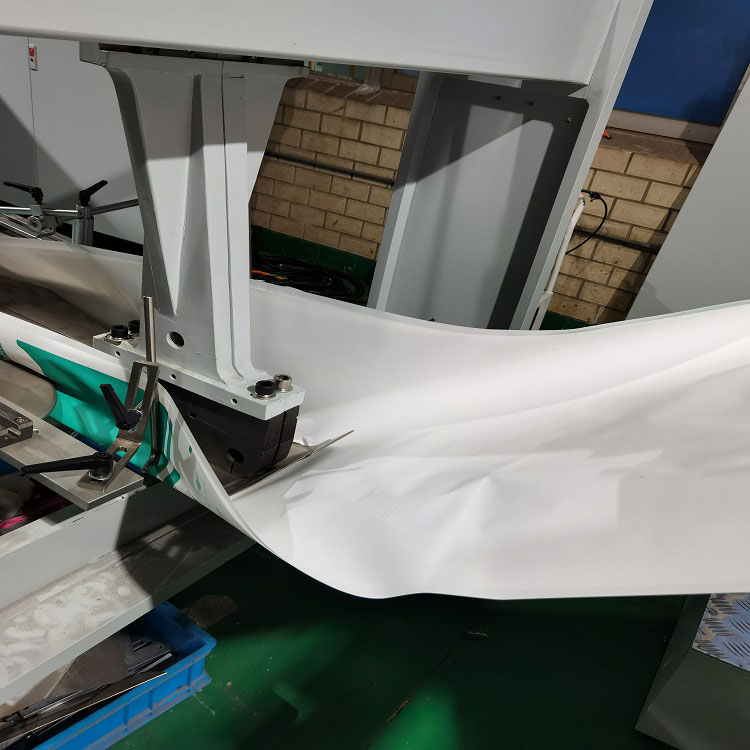

The real picture of the double layers paper bag making machine .

The material feeding unit one and material feeding unit two.

Two layers paper glued together.

The paper in tube, bag forming.

1.About 60 working days after receiving the deposit. We offer FOB price, Ningbo port. After signing of the contract ,the total amount of 30% advance payment, factory acceptance payment before delivery after the machine testing is ok.

2.Service and technical support including the allocation of wearing parts, online fault know, installation and debugging, the purchaser’s worker training, software upgrade, The product specification, fault repair and other buyers concerned about the contents.

3.Engineers are available to install and debug door to door and overseas. The cost for overseas will be for the buyer’s account, including visa charge, food, accommodation, around air tickets, and salary of 100usds daily one person.

GET A QUOTE