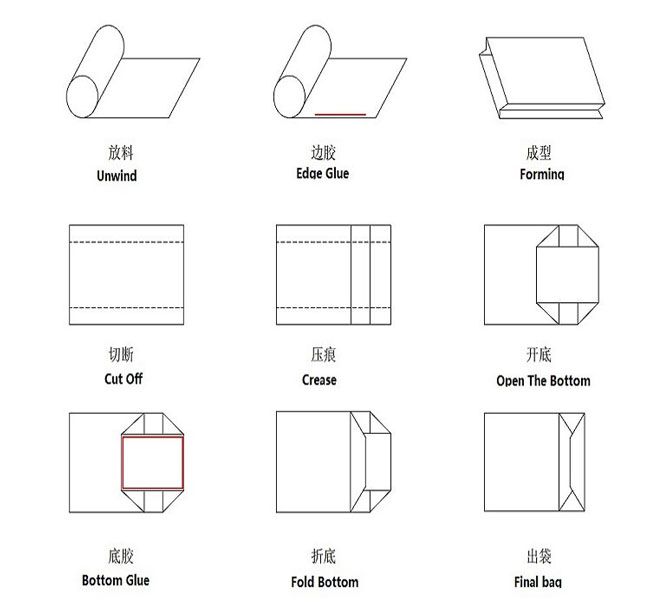

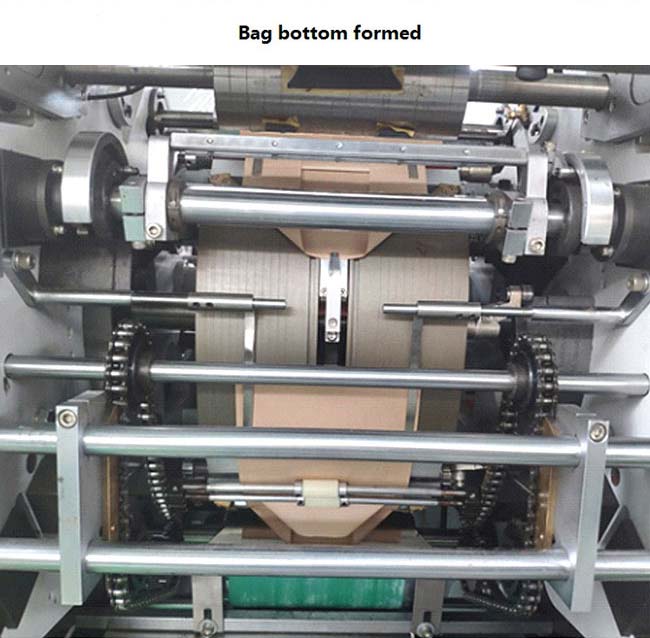

Fully automatic machine, adopt man-machine interface, one key to start, convenient operation and reduce labor costs .High speed ,high efficient and stable .It use paper roll in blank or printed as raw material. Consists of automatic centre forward glue, fixed length and cutting, bottom indentation , folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time.

|

Model |

YAST-FD450 |

YAST-FD330 |

|

Cutting length |

270-530mm |

270-530mm |

|

paper bag width |

210-450mm |

120-330mm |

|

paper bottom width |

90-180mm |

60-180mm |

|

paper thickness |

80-150g/m |

60-150g/m |

|

Machine speed |

30-200pcs/min |

30-220pcs/min |

|

Production speed |

30-150pcs/min |

30-180pcs/min |

|

paper roll width |

660-1290mm |

380-1050mm |

|

Roll paper diameter |

∅1300mm |

∅1300mm |

|

Inner diameter of paper |

∅76mm |

∅76mm |

|

Machine power |

380V 3Phase 4 lines 15kw |

380V 2Phase 4 lines 15kw |

|

Machine weight |

9000kg |

8500kg |

|

Machine size |

1000*3800*2200mm |

1000*3700*2200mm |

1.Use France Schneider Touch Screen Human-Computer interface, operate and control easily.

2.Adopt Germany Original REXROTH PC Control, Integrated with optical fiber, ensure high speed running steadily.

3.Germany Original REXROTH SERVO MOTOR and Germany Original SICK PHOTOELECTRIC Correction, tracking printing bag accurately.

4.Raw material load adopt hydraulic pressure up and down structure, unwinding adopt auto tension control.

5.Raw material unwinding EPC adopt Italy SELECTRA, reduce adjustment time.

Roll feed material:It uses paper roll in blank or printed as raw material .Hydraulic cylinder shaft automatically up and down,easy save man power.

Unwinding unit:Adopt the Italian ST correction system and constant tension control system,which has a fast response speed. And the correction saves time and raw material.

Bag forming unit:tube forming and the engine is pulled to the cutting tool and the bag is cut off.

Collection and counting unit:The bag collection is controlled by a servo motor and has a flattening function, which makes the finished bag easy to organize and pack.The automatic counting function can be set,and the counting is accurate.

Question: Can you provide a paper bag making machine that makes all sizes of shopping bags?

Answer: We can customize your paper bag making line according to your needs like shopping bag sizes.

Question: Besides the paper bag making machines, are there other associated machines for paper bags manufacture?

Answer: if you only make small paper bags for food, a paper bag machine with printing function is enough. If you tend to make shopping bags with handle, paper handle making machine, and paper bag handle pasting machine is a must.

Question: Can your paper bag making machines provide quality assurance?

Answer: PLC touch screen use SCHEIDER brand (France)

PC Motion controller use REXROTH brand (Germany),

Servo motor use REXROTH brand (Germany)

Inverter use DELTA brand (Taiwan), Photosensor use the SICK brand (Germany)

EPC use SELECTRA brand (Italy), Electrical box with AC condition,

Machine with CE certification, Machine with ROHS certification.

Flour Paper Bag Making Machine, Square Bottom Paper Bag Machine, Paper Bag Making Machine for Food, paper bag machine fully automatic kraft, Automatic Square Bottom Paper Bag Making Machine, paper bag making machine, paper bag making machine price, paper bag machine

GET A QUOTE